Laboratory counters are your primary workspace used to hold your tools, projects, and all the necessary equipment. These days, we can find countertops available in a striking array of costs, materials, composites, and finishes, giving you the opportunity to choose not only the best option for your laboratory but the most cost-effective one. As each laboratory is different from the next, you want to determine what you get with each material. Then be confident in your choice of what feels right for the type of work you’ll be using the countertop for.

This time around we’re singling out two most popular countertop options – epoxy resin and polyurethane – and helping you decide between the two:

Epoxy Resin

Epoxy resin countertops are made to last. As it is durable, non-porous, and reasonably economical, epoxy resin is the most common choice for many kinds of labs. The material holds up well in wet situations as it is water and moisture resistant, which is why most labs use it around sinks if not for the entire countertop setting. Epoxy resin is impressively resistant to various chemicals, heat and a majority of harsh conditions that cause cracking, blistering and discoloration of surfaces. The material doesn’t consist of added layers or coatings so, therefore, is durable and reliable.

The types of labs where Epoxy resin countertops are popular are pharmaceutical, educational, hospitals, medical, R&D labs, microbiology, biomedical, biological science labs, molecular pathology, and industrial testing.

Polyurethane

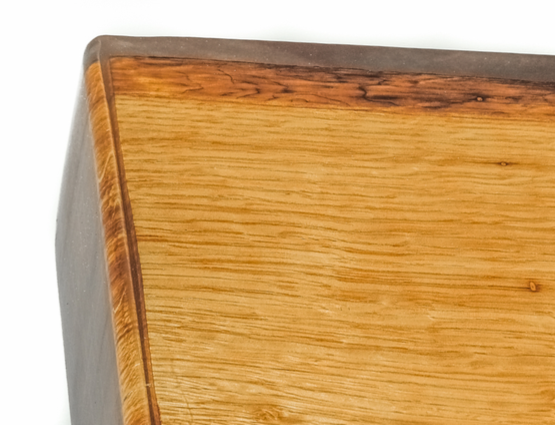

Implicit of its name, polyurethane is plastic and can be solvent (oil) or water (acrylic) based. Since it is very durable, polyurethane varnish stands as one of the best finishes for a countertop, mainly because it can be as subtle as lacquer. Smaller labs and DIY enthusiasts will want to know that polyurethane application is a job done efficiently, without spray equipment or any previous experience. It typically takes eight to 24 hours for a single coat (which is enough for a beautiful finish) of polyurethane to dry thoroughly. Once it has hardened, polyurethane can’t be reconstituted. If you are thinking between oil- and water-based polyurethane varnish, take into consideration that oil finishes usually soak into the grain and yellow.

Which One to Choose?

The difference between epoxy resin and phenolic resin is the manufacturing process and construction materials. Functionally, the two elements are very similar in quality and durability, with the heat handling capacity being the main difference between the two. As mentioned, phenolic resin countertops handle continuous heat exposure up to 350°F (176°C) exceptionally well while epoxy resin performs even better under higher heat loads, including open flame. On that note, if your lab is continually exposed to harsh conditions, the epoxy resin could be a better option.

For the best results when designing your lab, talk to a reputable and professional lab planner or designer company to explore all of the options and make the best choice for your lab.